We, Durga Engineering

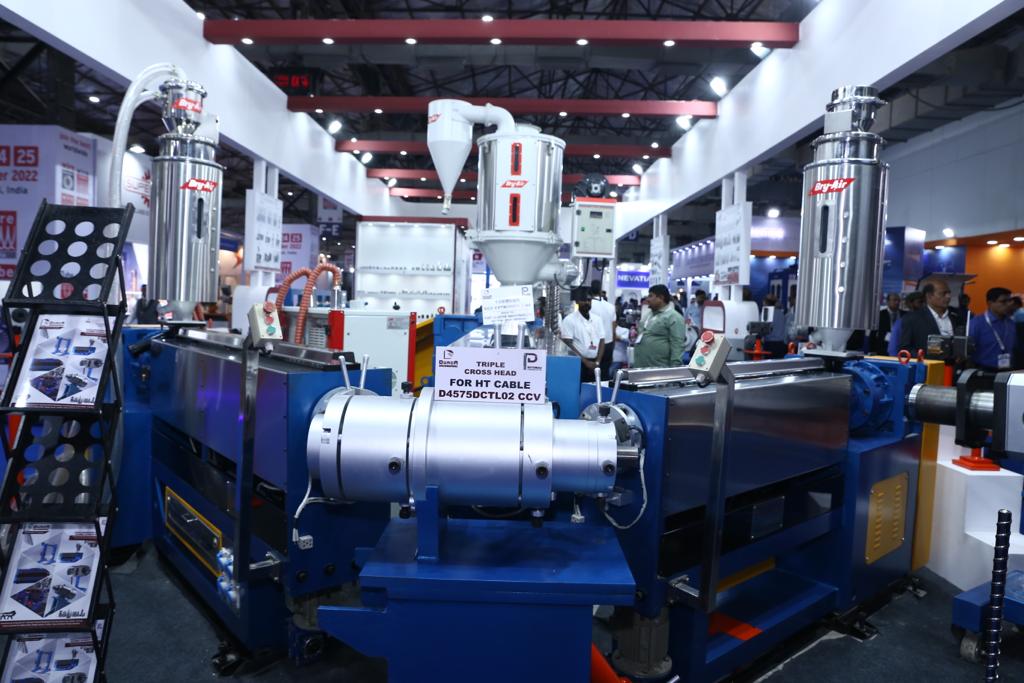

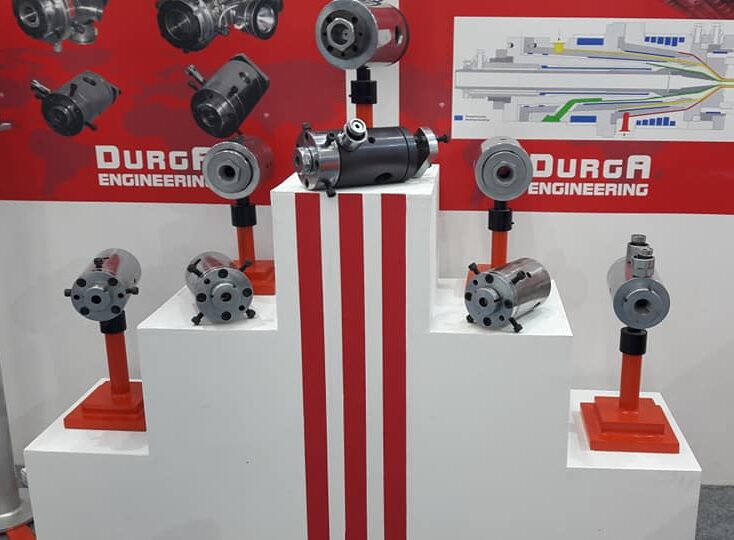

Manufacturer & Exporter Of Extrusion Plant & Machinery, Crossheads, Screws & Barrels, Tips, Dies & Spares etc.

About Company

Manufacturer Of International Standard Quality

Durga Engineering Works has started its operations in 2006. We provide a complete solution of Extrusion Machinery for Cables, Rubber, Optical fiber cable, Pipe, profile, Medical tubing etc, Screws & Barrels for plastic injection moulding, Crossheads, Spares, Tips, Dies, etc.

Why Choose Us

What We Do

Quality Material

Reduce the raw material consumption

Accredited

Reduce Scrap

Trained Workers

Technically Skilled

Standard

Increase Tooling

Quick Response

Reduce set up time

Warranty

Increase Productivity

We fulfill your every need

Get A High Quality and Customization Products

Client

Testimonials

Our client-centric approach is the reason behind the success of our organization.

For gaining maximum client satisfaction, we customize our range of products in accordance with the specifications of our clients. We are working as a quality conscious firm and leave no stone unturned in maintaining quality of our range of products. Owing our ethical business policies and transparent business dealings, we have been able to draw attention of some reputed companies of the nation.

People Say The Nicest Things

We value our customers

Aarti Mittal

CEO

Well maintained the quality of their products. I am very happy that they provide customization option.

Deepshikha

DIRECTOR

Highly recommended, I like the most that they have strong customer services & serve good products.

Vineet Jain

PRODUCT MANAGER

I am regular customer of durga, very happy with their services and products. Must buy